Artwork

SaaS

ID

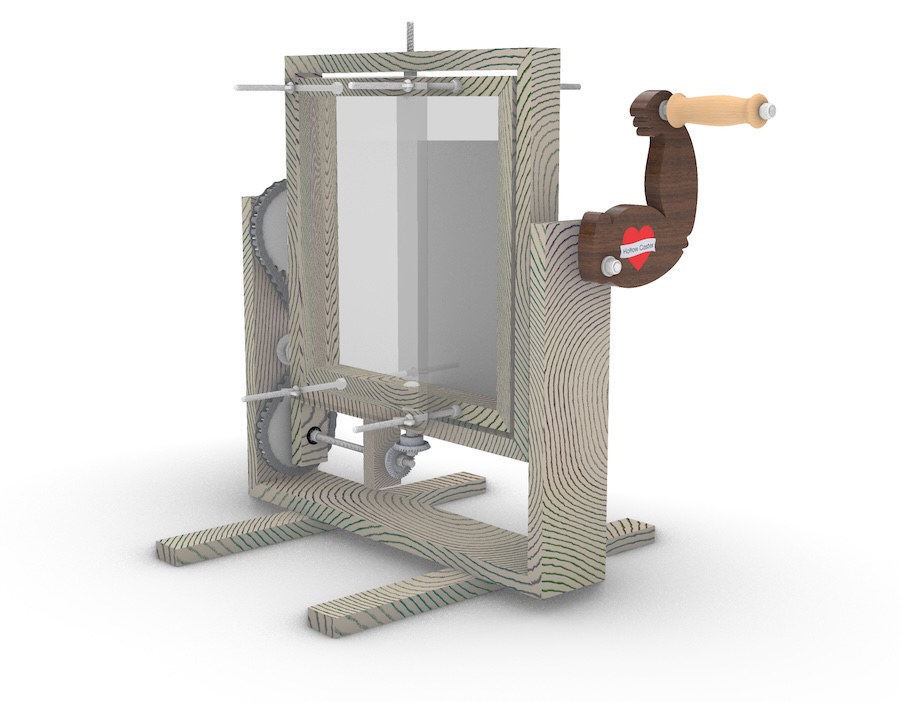

Roto-Caster

Year

2024

Concept

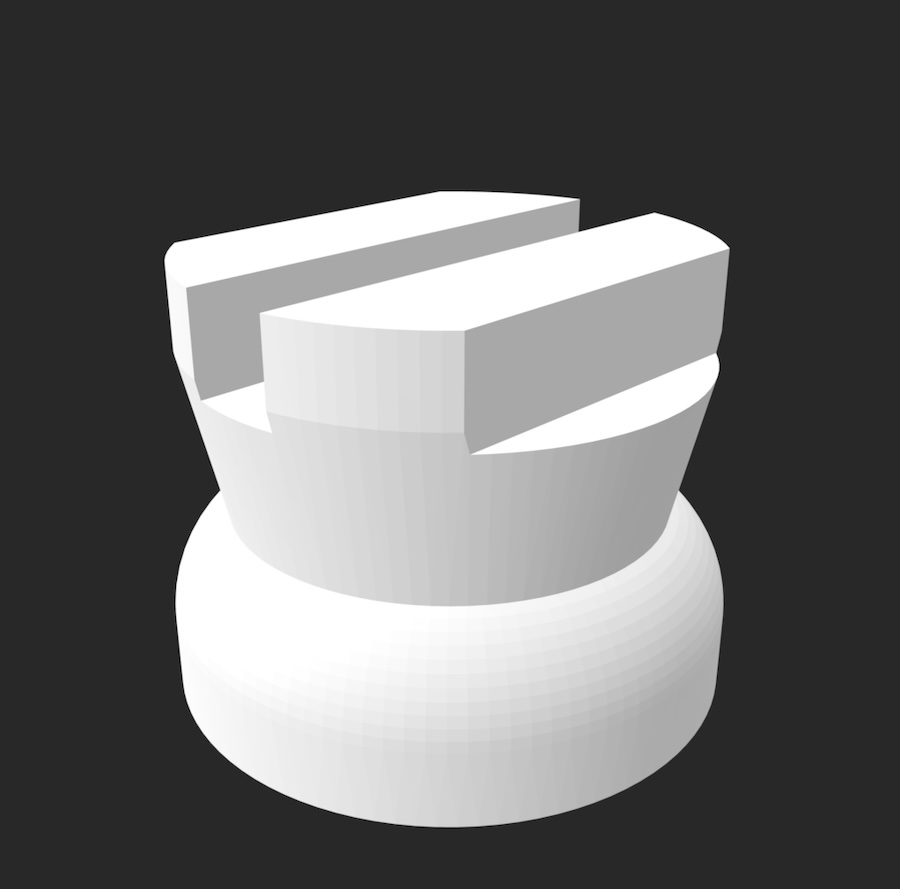

Roto-caster to cast hollow positves

About

Roto-casting also known as "rotational molding," is a manufacturing process where a

hollow mold is filled with

plastic resin or other hardening liquid, and rotated on multiple axes to evenly distribute

the material across the mold's inner surface,

creating a seamless, hollow plastic part. Essentially, the rotation forces the liquid to

adhere to the mold walls, resulting in a uniform, hollow product.